The ROTAC® Tipper Difference

Most Efficient Tipper In the Industry

At Micromatic, we pride ourselves on being the leader of efficiency in the tipping industry. This achievement is attributed to our high-efficiency actuators, which not only minimize frictional forces but also reduce pressure requirements for lifting loads.

The result? Lower engine RPM, decreased fuel consumption, and minimal wear and tear – lower pressure to lift means more efficiency and lower cost of ownership.

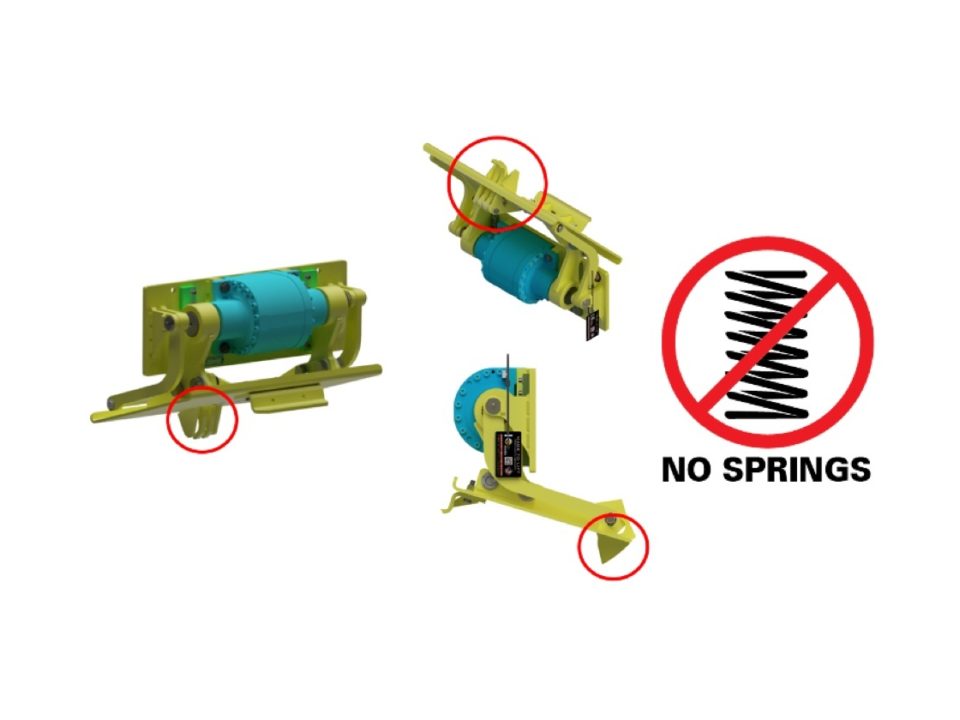

Heavy Duty Steel Hooks vs Risky Latch Springs

While many competitors opt for latch springs in their tippers, Micromatic takes a different approach with the use of heavy-duty hooks, specifically in our ROTAC® tippers. Unlike latch springs prone to wear and tear, our heavy-duty hooks feature a robust design with built-in hard stops, reducing latching stress. With no springs in our tipper design, concerns about fatigue parts and changing forces are eliminated. The durability of our hooks ensures reliability during the tipping process, enhancing both safety and efficiency.

Rotary Vane Actuator vs Helical Actuator

In the world of actuators, the choice between helical and rotary vane is crucial. Competitors may opt for helical actuators, but Micromatic embraces the simplicity and efficiency of rotary vane actuators. Our design boasts only one moving part, a self-contained structure, and zero metal-to-metal contact, avoiding internal debris that can compromise seals. The rotary vane actuators deliver the highest torque output at standard operating pressure, available in various models catering to both pneumatic and hydraulic capabilities. ROTAC® Tippers uses a simple, industry proven actuator designed specifically for the waste industry and the harsh conditions it is required to operate in (rotary vane actuator shown below).

Additional Advantages

Micromatic's ROTAC® tippers offer a multitude of advantages, setting them apart as the market leader:

- Highest spline engagement among tippers

- Compatibility with most truck body sill widths

- Slim design for installation on dual-rote trucks with kick-bars

- Nickel-plated Grease Zerks designed to flush contamination and debris

- Fewer parts, translating to fewer failure points and lower cost of ownership

In Stock and Ready to Ship

Micromatic is the only manufacturer in the industry who designs, manufactures, and assembles the entire tipper assembly from start to finish. Unlike our competitors, the designs, materials, and construction of the lift iron and the actuator assembly are 100% made in the USA. Experience shorter lead times since we do not outsource the manufacturing of our actuators. Our products are in stock and ready to ship, ensuring your business experiences minimal downtime.

Experience Excellence with Micromatic

As an industry leader in actuator manufacturing and as active members of the NFPA (National Fluid Power Association), we continue to learn and adapt to the industry’s best practices and innovations. We understand efficiency, and that is why providing an actuator designed for the waste industry is so important to us. We take pride in our commitment to excellence, as we execute every aspect of the tipper assembly process – ensuring quality and durability when you make the choice to use ROTAC® tippers for your rear load and side load tipper needs!